LEAD 41 began their twelfth day by leaving the influential city of Milan shortly after 7:30 AM. There was a heavy fog that is typical of this time of year with a light frost on the ground. As the class traveled south to Parma and the fog began to lift, one could see a very flat terrain that has been farmed for many generations. The valley in which they were traveling had been formed over a period of millions of years by the Po river with the Alps located to the North and the Apennine mountain range that runs vertically along the west side of Italy. As they neared Parma, the group traveled west into the foothills of the Apennine mountain range to the city of Langhirano. On the outskirts of this city of 10,000 people they visited the family owned company of F.lli Canetti.

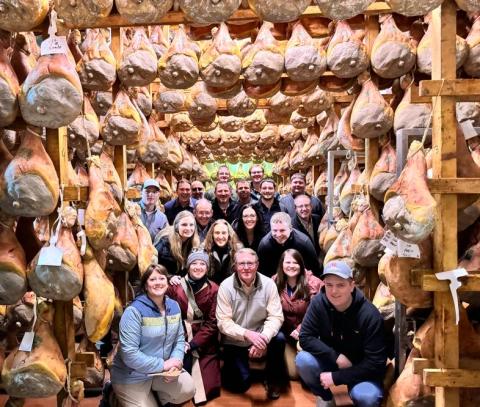

F.lli Canetti is in the business of purchasing the ham on the bone from processing plants. The company was formed in 1970 by the presenter’s grandfather and his brother, and is today owned by his father and uncle. The class walked through the process in which ham becomes the delicate meat of prosciutto. The first requirement is that all hogs must be fed out solely on the farm. Second, it must be of the highest fat content. Thirdly, they age the meat for 5 days. Upon completion if it does not meet inspection, it is turned back to the processing plant. Once the ham passes inspection the following process begins.

The leg is messaged to get any remaining blood out. They then put it into both wet and dry salt for one week. After one week they blow out the salt and do another salting with just dry sea salt, and let the ham rest for two weeks at a constant temp between 1 to 4 degrees Celsius and 60 to 75% humidity. Upon completion of two weeks, the ham is blown out, trimmed up, and placed vertically in which it is moved periodically for uniformed drying for two and a half months at a constant temp of 2 to 4 degrees Celsius and 45 to 60% humidity. Once trimmed the ham goes to a longer term storage for three and a half months in a ventilated room maintained around 12 degree Celsius and 50% humidity once this process is complete the ham goes through 30% shirk from start to finish. The last process covers the ham with a mixture of pork fat, salt, pepper, and rice flour called suino, which helps sill out oxygen and allows the ham to be preserved for up to 30 months or more.

Parma is considered to be the premium of all hams. It must have a large round shape, a high percentage of fat, and must be aged for at least 14 months. All others that do not meet these specific requirements must be sold as nationals. Only pigs originating from the region of Parma are allowed to be sold with this classification. Inspections are conducted by a state regulated inspectors on 10 to 15% of all hams in a lot with a small pointed horse bone which is thrusted into the ham in five different locations and then smelled then all holes are reclosed as to not allow oxygen to enter the meat. If the ham passes inspection it is stamped with the number of the processing plant, inspector, and the Crown of Parma. There are no chemicals used during this process. Each ham weighs between 9 and 12 kilograms and cost approximately 14 to 16 Euros per kilogram. After the completion of the tour we headed back to Langhirano to try the finished product of Parma prosciutto.

At Salumieri Ugolotti, a small restaurant first established in 1869, the class had the pleasure of trying the 32 months aged Parma prosciutto along with salami and Coppa. They also had Ravioli with ricotta and greens cooked in a butter sauce, cakes for dessert and coffee. By all reviews, the meal, especially the prosciutto, was loved by all.

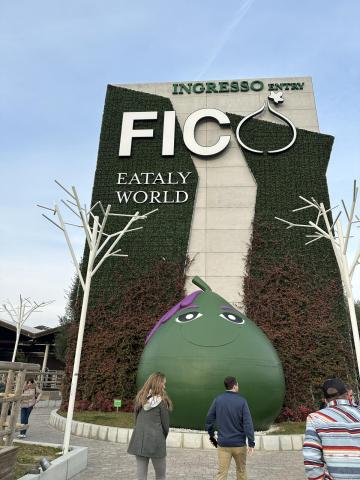

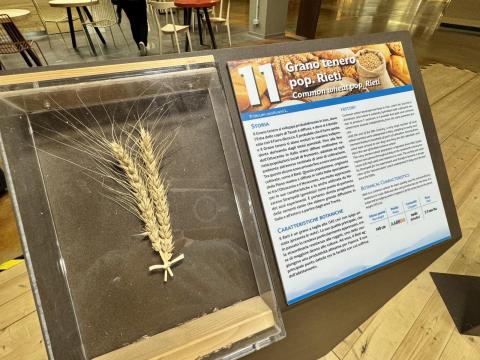

Following LEAD 41’s lunch in Langhirano, they traveled further south to the city of Bologna. Here they made a stop at FICO Eataly World. This is an Italian Food Theme Park with displays as well as shops and restaurants for all the famous Italian cuisine. They took a 45 minute tour in which the group learned the history behind and had a taste test of the Bolognese specialty sausage mortadella. They also spent time in the cheese area of the park learning about Parmesan and having the opportunity to try some fresh Parmesan cheese. Upon completion of their guided tour, they wrapped up with a wine tasting in the park's very impressive wine shop/tasting room.

At the conclusion of the guided tour, LEAD 41 had the next hour to explore the park on their own. Some decided to try some gelato, while others took in the history of wine bottles and learned more about the wines of different Italian regions. Whatever food came to mind, this park provided the opportunity for both knowledge and tasting, making it a very valuable afternoon for learning more about the Italian dishes we will be encountering over the coming days.

After the stop at FICO, the class then traveled into Bologna and checked into Hotel Accademia in the University district of Bologna. For the evening, fellows were given the opportunity to explore this district for ourselves for dinner. This was a great chance to soak in the culture of the city as well as practice Italian with restaurant staff. As well as try some new dishes they perhaps learned about at our previous stop.

Overall, today was a great day for experiencing the whole food production cycle for some famous Italian products. Getting to see how they originated, how they are made, and eventually how a final dish may look at a restaurant.

*Today’s blog contributors are Luke Zangger and Rhett Montgomery, in addition to your blog team of Kari Christenson, Jakob Burke and MiK Fox.